We provide a complete tooling service

- Value engineering of product design for die casting

- Tool design and development

- Casting simulations

- Engineering and support from initial order to tool delivery

- All required sampling and inspection protocols

From our toolroom, we provide component design advice, tool design and development, casting simulations, tool build, testing & tool optimisation, quality protocols to mass production.

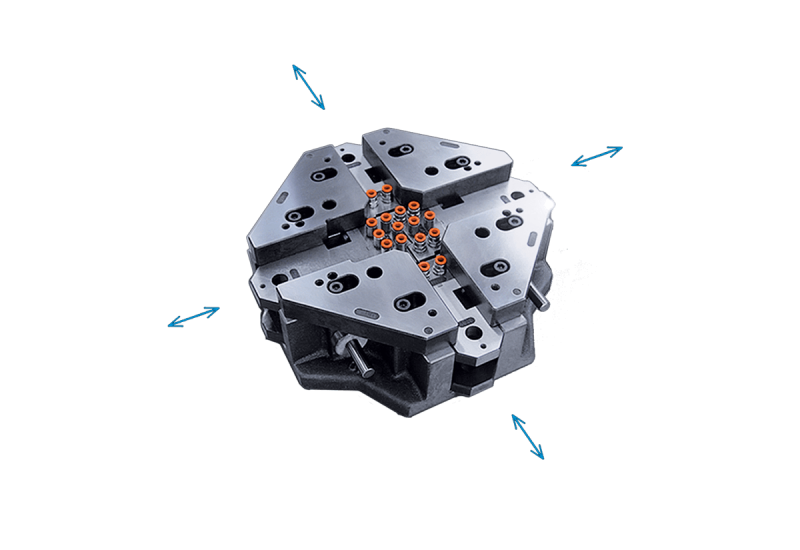

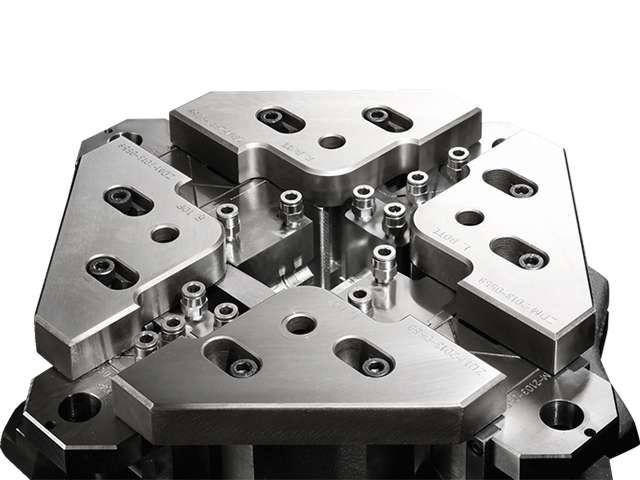

Tools for LamaCaster machines can have up to six slides enabling the production of very complex parts. We can provide tool packages for all our machines and systems with ongoing supply of spares and an after-sales repair service.

Tool sizes are as follows:

| LamaCaster P65 | Slider size 65mm x 65mm. Max shot weight 60g |

| LamaCaster H65 | Slider size 65mm x 65mm. Max shot weight 90g |

| LamaCaster H100 | Slider size 100mm x 100mm Max shot weight 220g |

All tools we supply are made from premium grade steel, fully hardened, tested, optimised and include full inspection protocols and samples.

Customer Support

Our customer support team will provide you with excellent support. We stay close to you at every phase of your project to ensure you receive all the required information and support from concept through to project realisation and beyond.