Revolutionary Titusonic® Technology

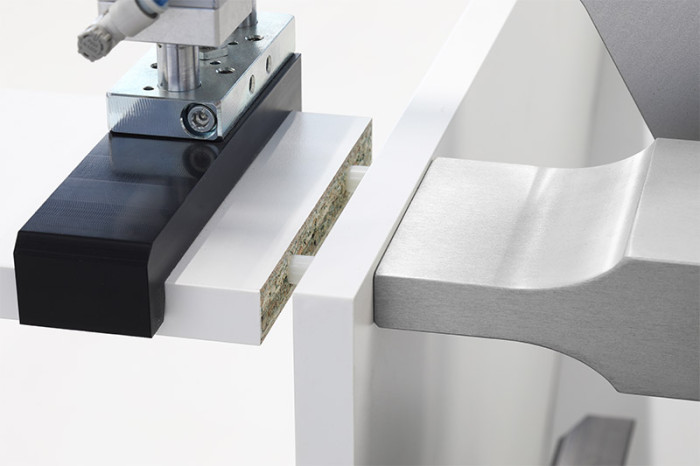

Titusonic products are based on the revolutionary WoodWelding fastening process for ultrasonically bonding wooden materials without the use of adhesives. The advanced process provides an exceptional bond strength. It can be adapted into many product categories. The first two industrial applications in wood technology are Titusonic® cabinet fastening (Sonic Rivet) and Titusonic® Hollow Core Board (HCB) fastening, jointly developed with and licensed from WoodWelding SA, Switzerland.

Key advantages:

| Fast | High productivity with fast welding time. |

| Clean | Adhesive-free proces. |

| Strong | Sturdy cabinet construction. |

| Reliable | Enhanced confidence in the end product. |

Fast

- High-level production outputs for volume applications.

- Ultrasound welding speed is fast, taking only two seconds per cycle

- A brief dwell time is sufficient to strengthen the weld

Clean

- The welding process is completely adhesive-free

- Low production complexity without the need to set up or clean glue application machines

- No drying time required

Strong

- 30% stronger than a standard cam and dowel joint, and comparable in strenght to a glued cabinet joint

- Welded cabinets can be shipped immediately after assembly

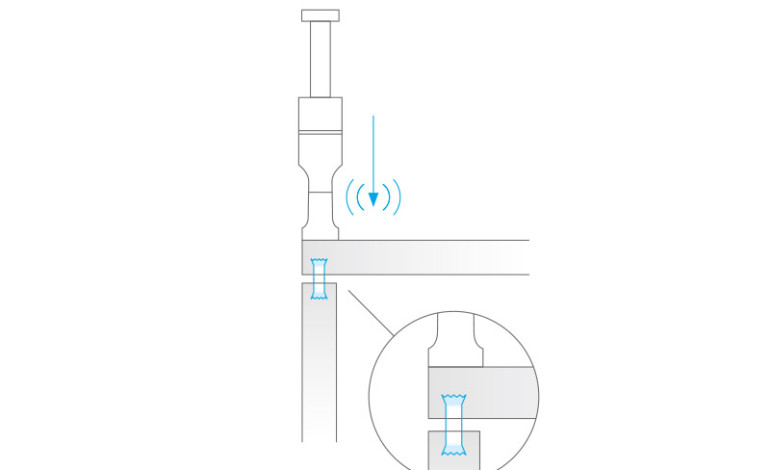

- Dowel contraction during welding creates tension across joints, ensuring strong and sturdy cabinets

Reliable

- Integrated Quality Check Algorithm - Statistical Process Control (SPC) to monitor the performance of every weld

- Traceable performance for process optimisation and repeatability

- Automated detection and ejection of inconsistent cabinet raw material during production

How does it work?

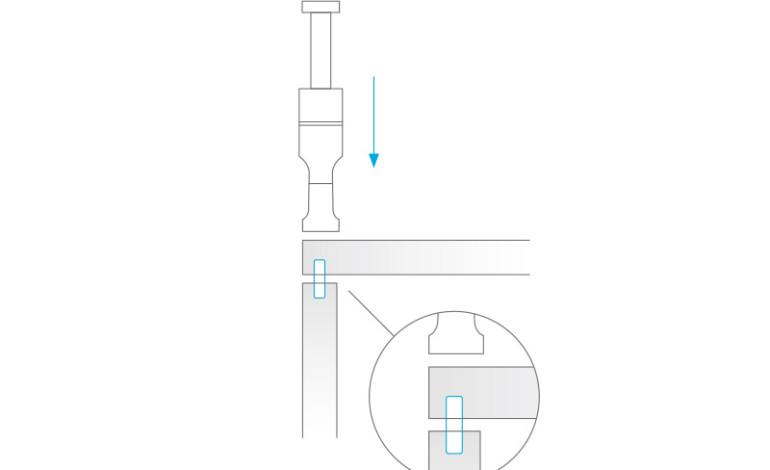

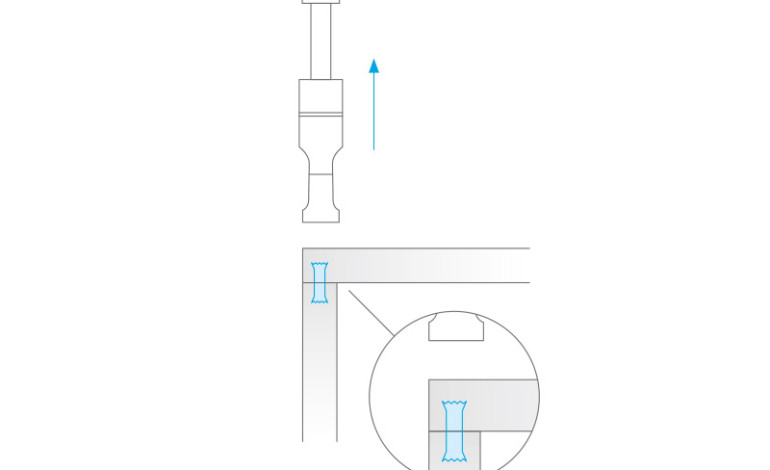

Ultrasound high-frequency energy is applied to specific areas of the panel joints, causing the sonic dowels to liquefy. The melted material is then forced into the porous spaces of the wooden board by pressure before hardening and contracting, resulting in an effective joining of the panels.

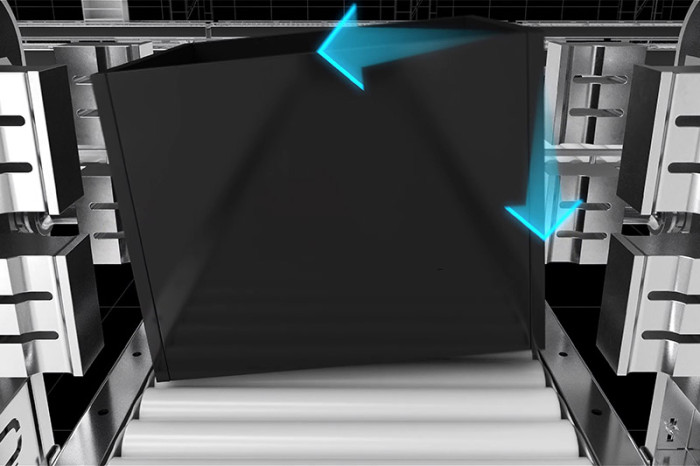

- Preassemble the cabinet and place it into the press.

- Ultrasound energy welds the boards together.

- After 3-4 seconds the cabinet can exit the press.

Ultrasonic Process

When using the WoodWelding® process ultrasonic energy of approximately 20.000 cycles per second is applied. Adding pressure to the process, the liquified plastic connector element is forced into the wood utilising the natural porosity of most wood-based materials such as chipboard, MDF, HDF, and plywood. Most solid woods can also be used with this process, which takes bonds only seconds to complete.

Traditionally wood products are joined together using mechanical fasteners such as wooden dowels and glue, screws or other connecting fittings. However, these methods produce their own problems, which are largely resolved by the use of WoodWelding® technology. It takes fastening of wood products into the future with a process that can be linked to welding of the steel in car manufacture and shipbuilding.

The Investment is co-funded by the Republic of Slovenia and the EU

The development of Titusonic technology is co-funded by the Republic of Slovenia and the European Union Regional Development Fund.

Download brochure

Subscribe to our newsletter

Subscribe to our newsletter and be among the first to learn about our latest products, state-of-the-art innovations and company-related news.