Our tools guarantee dimensional consistency over high volume production runs. They can manufacture components with weights from 1 to 1000g.

Conventional Tools

With conventional tools, the number of slides depends on product specifics. They are available for machines with locking force up to 120 tonnes and maximum line pressure of 300 bars. They should be used with zinc alloys.

| Max. tool size: | 800 x 600 x 600mm |

| Weight of castings: | Up to 1000g |

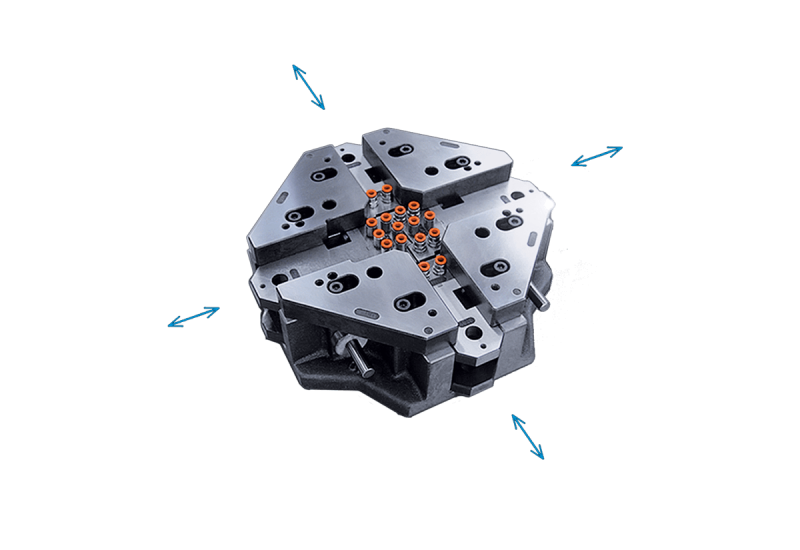

Multi-Slide Tools

Our multi-slide die casting tools can have up to five slides. They are available for machines with locking force up to 2 tonnes and line pressure up to 8 bars. They can be used with zinc, lead or tin based alloys.

| Max. tool size: | 300 x 300 mm |

| Weight of castings: | from 60 to 225 g |