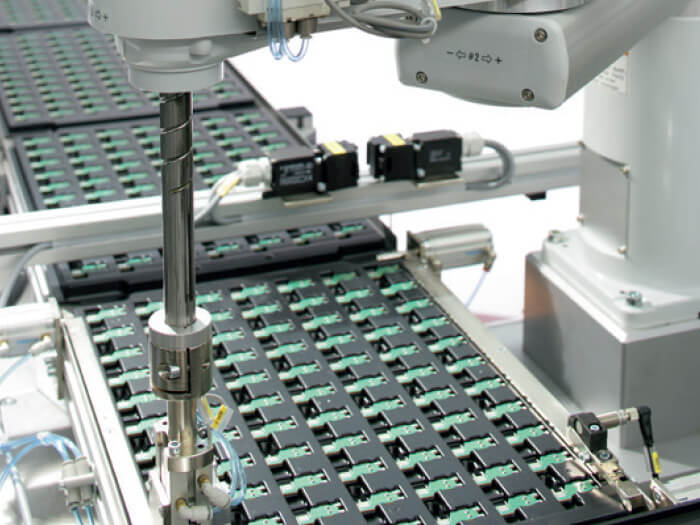

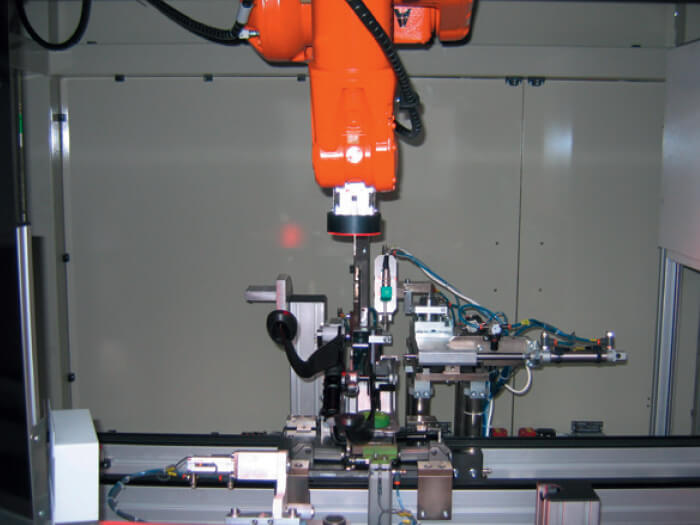

Component Handling

Our component handling solutions include pick-and-place units and robots, as well as rotation units and grips. Vacuum, electromagnetic, pneumatic and mechanical solutions are also available.

Feeders

We can provide vibrators and rotators, as well as bowl and linear feeders. We can also create special units that divide and dose miniature objects, such as screws or springs. Special solutions are also available.

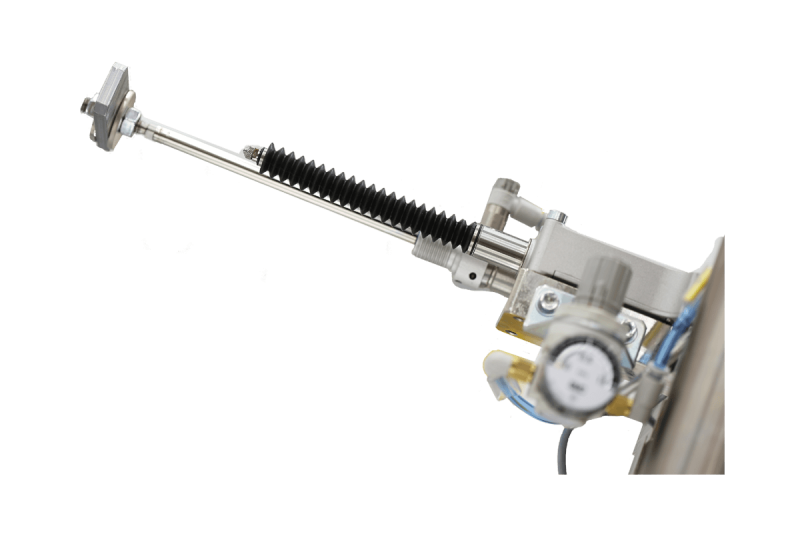

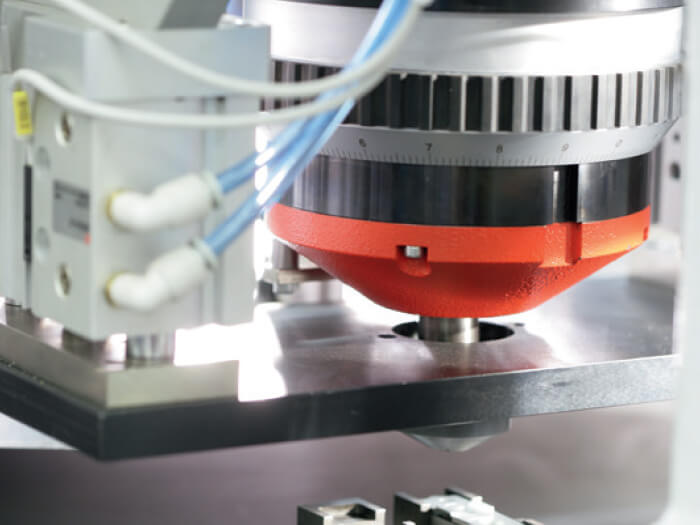

Mechanical Operations

Some of the solutions we have already provided are screw driving, orbital riveting and thread cutting. Winding to appropriate height or depth, moment or angle is possible.

Dosing

We can provide solutions for precise dosing of small quantities of various liquids or powders, for example silicone, paint, grease, oil, gels, powder, additives or sand. We can always create special solutions for our clients' specific situations.

Thermal Processing

In terms of thermal processing, we can provide solutions for heating, drying, or cooling. This can be air and water cooling, silicon drying, ultraviolet or induction heating.

Welding and Connecting

Our assembly machines can provide TIG or ultrasonic welding, orbital riveting, gluing or soldering.

Control and Testing Stations

We can provide a variety of different finished part controls or intermediate inspections. Some of the features we can test: dimensions, temperature measurements, product shapes, liquid and air sealing, strength, hardness, temperature and electrical resistance.

We can also provide custom test stations for functionality checks of assembled parts, built upon customer requirements. These can be video inspection solutions, robot guided controls, sensor controls (inductive, optical and pressure sensors), flow and force meters, colour and contrast, temperature and laser sensors, as well as acoustical/noise checks.

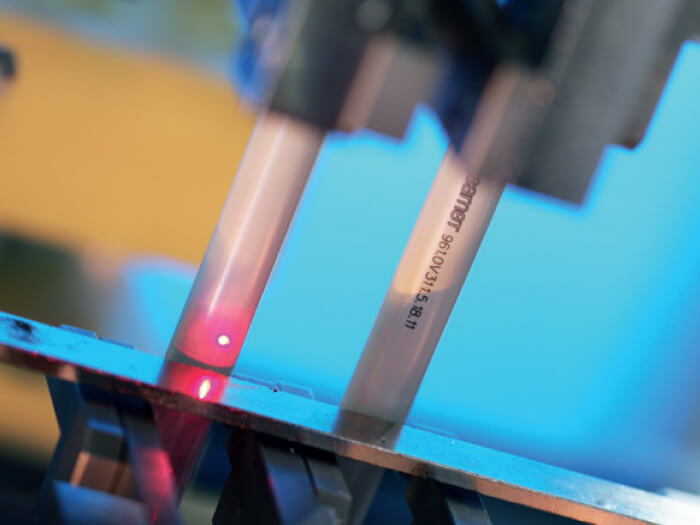

Marking and Labelling

We can provide systems for mechanical stamping, ink-jet printers and laser printers.

Packing

Our packing systems can pack items in boxes, smaller containers or blisters, either with a packing track or mechanical (with robots). Solutions with or without counting of parts are available.

Ask our Engineers

Are you searching for an automated assembly solution that will help you optimize production? Let us find it for you. Our engineers have found efficient solutions for even the toughest challenges. See some examples below and tell us what you need.

Need assistance?

If you need assistance or cannot find what you are looking for, feel free to send us an email to [email protected] and we will get back to you as soon as possible.

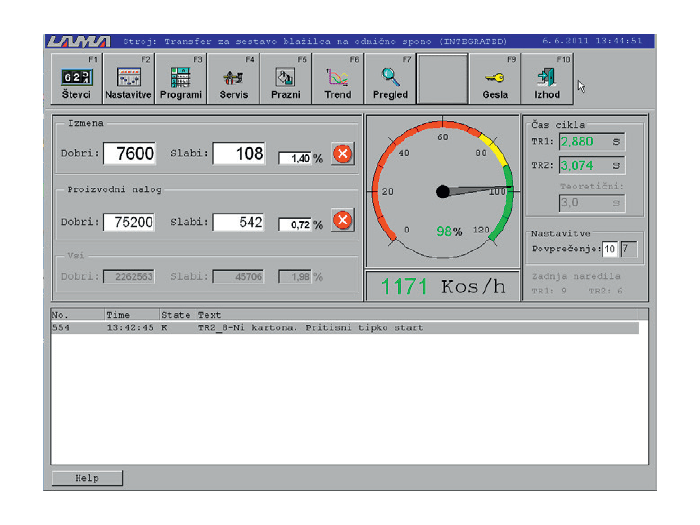

Process Programming

Our proprietary software “Monitoring” collects, elaborates and transfers the data to a PC. It also enables events’ recording and statistical processing that are displayed in graphs, chart pies…

It can be integrated with existing ERP and upgraded to allow for advanced functions. All the equipment built in the line is freely programmable, assuring line upgrade to specific needs.

Our ONLINE Service enables remote maintenance, diagnostics and program errors’ solving. It has a highly intuitive and user-friendly graphic interface that provides error history and displays alarm messages. The language of the interface can be adapted to customer’s wishes.