Titus Technologies core competences of die casting, tooling and automation allow us to fully integrate all aspects of an insert casting system ‘under one roof’. This means you only have to work with only one supplier during the purchase, build and delivery of an insert casting cell.

Insert Casting

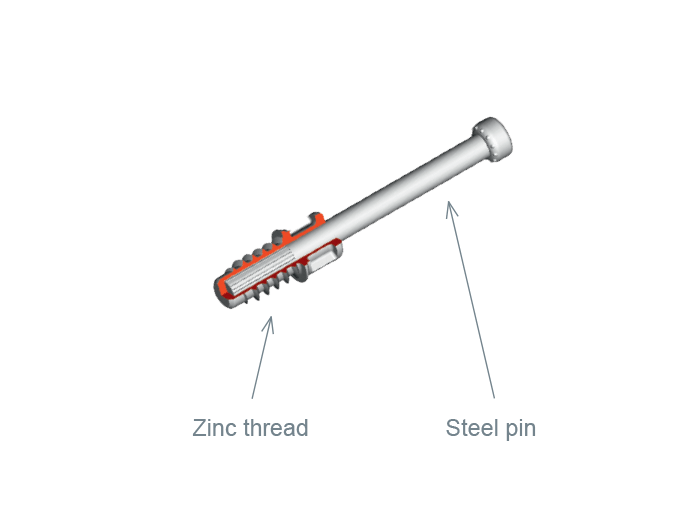

In certain applications, parts made from only zinc alloy will not meet the performance requirements of the final product. In these instances, it is possible to place an insert into the tool and cast zinc around it to improve component function or performance. Inserts are normally steel or other non-ferrous materials and are placed into the tool using a robot or other automated devices to create a ‘Combi-part’.

The resulting 'CombiCast' part can have unique design features combining the best properties of both materials with the resulting part outperforming an all zinc die casting. Inserts can take many shapes and forms; springs, headed steel inserts and even wire for example.

Lama CombiCaster Insert Casting Systems

LamaCaster insert casting systems are designed and built to specific customer needs. The integration of automated robotic devices to our machines guarantees accurate manipulation of inserts and gives maximum flexibility of the type of inserts that can be used.

| Locking force: | dependent on the application machine type |

| Tool size: | determined by product/machine type |

| Shot weight | up to 60g - 200g (excluding inserts) |

| Dry cycle speed: | up to 50 cycles per minute |